Components

The Vision System is divided into Vision System 1 and Vision System 2. Vision System 1 is composed of a vision camera and a laser displacement sensor, while Vision System 2 is composed of a 3D sensor.

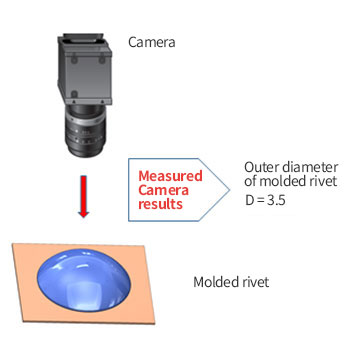

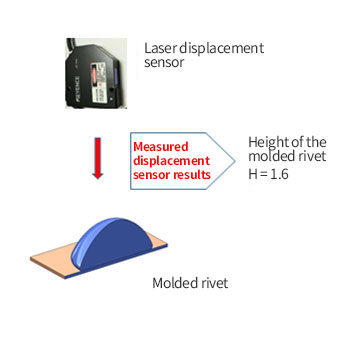

[1] Vision System 1

Measure the outer diameter of the molded rivets using a vision camera and measure the height using a laser displacement sensor.

- Assign a unique ID to each molded rivet according to the respective staking operation.

- Measure the outer diameter of the molded rivet with a vision camera and inspect whether it falls within the specified range.

- Measure the height of the molded rivet with a laser displacement sensor and inspect whether it falls within the specified range.

- Check if the measured external diameter and height data match the corresponding unique ID and store the data.

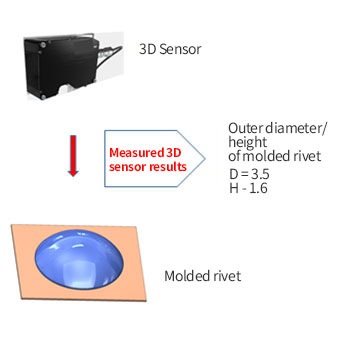

[2] Vision System 2

Scan the molded rivets themselves using a 3D sensor to simultaneously measure the outer diameter and height of the molded rivets.

- Assign a unique ID to each molded rivet according to the respective staking operation.

- Scan the molded rivets using a 3D sensor to measure the outer diameter and height simultaneously and check if they fall within the specified range

- Check if the measured external diameter and height data match the corresponding unique ID and store the data.